CSE SOFTWARE is developing virtual environments for real-world training.

A new center is set to be constructed at OSF Saint Francis Medical Center devoted to the topic. Peoria Robotics is working to provide a more realistic system to train medical personnel, and real-life medical events are being replicated at the University of Illinois College of Medicine at Peoria. Simulators are “revolutionizing medical education,” claims the college’s regional dean, Dr. Sara Rusch.

Outside of healthcare, simulators are being put to great use in many industries, from aviation and defense to engineering and urban planning. Perhaps most widely associated with flight training, realistic simulators are now being used for heavy equipment operator training.

Recognizing the many benefits of simulator training, the Equipment Training Solutions Group at Caterpillar Inc. first introduced a product line of equipment operator training simulators in 2004. Four years later, Cat licensed its simulator business to Morton, Illinois-based CSE Software, which formed an affiliate company, Simformotion LLC, to handle the manufacturing, distribution and marketing of Cat Simulators.

It’s quite an accomplishment for the firm, which had to compete against numerous companies around the world to win the contract. “We have worked with Caterpillar for close to 20 years now,” said Simformotion marketing strategist Annette Bailey. “We have delivered and proven ourselves, and that’s why they trust us.”

Enter Simformotion

The earliest versions of Cat’s simulators were created as marketing tools for new product introductions and dealer training. But the company soon realized it had a valuable tool for operator training on its hands, and decided to license the technology.

Ultimately, Caterpillar licensed it to CSE, which formed Simformotion LLC in January 2009 to keep the simulator business separate from the rest of the firm. The two companies share the same principals: CEO Ken Pflederer and vice presidents Lara Aaron and Renee Gorrell. CSE actually develops the software for Cat Simulators, which are then manufactured and distributed by Simformotion.

While Simformotion itself is less than two years old, its parent company has a long history with Caterpillar. Founded by Pflederer in 1990, CSE has worked on hundreds of projects for the manufacturing giant over the years, from custom software development to technical support and eLearning solutions. Prior to the licensing agreement, CSE was already well familiar with Cat’s simulator business, having provided technical support and quality assurance testing for the products. So when Caterpillar sought to license the technology, CSE was a natural choice.

“CSE Software is a ‘bleeding-edge’ software development house and has been for 20 years, so taking on the challenge of creating ‘serious gaming’ software was pretty much a no-brainer,” says Pflederer. “We had programmers and graphic artists chomping at the bit to get their hands on something new, and in less than a year, they have created the best simulator software on the market today.”

Serious Games

Serious Games

Thirty-three years ago this month, Atari, Inc. released the Atari 2600 video game console. While it wasn’t the first gaming console for the home, it was the first to achieve massive success. Three years later, Pac-Man fever swept the nation, on its way to becoming a global phenomenon and an eternal icon of the 1980s. Today, the first generation raised on video games is all grown up, and gaming is no longer just a kid’s game.

The concept of “serious games”—those with objectives that go beyond entertainment—dates to long before the video game era, but it was Clark Abt’s 1970 book Serious Games that probably first employed the phrase in its exploration of games for problem solving and education. The defense industry was quick to realize the potential of gaming for non-entertainment purposes. An early-‘80s version of Atari’s popular Battlezone—notable for its innovative use of first-person 3D graphics—was designed to simulate combat for the U.S. Army and is widely considered to be the first serious game. In the decades since, the healthcare, education and professional training industries have become some of the biggest users of serious games.

Simulation games can be viewed as a subset of serious games, and have actually been in use since the early 20th century. The first known flight simulation device was developed in 1909 to help pilots operate an early version of the airplane. In the early 1990s, “virtual reality” was all the craze, but the technology never lived up to the hype.

“There are still simulators in the market today that date back to the 1970s,” notes Pflederer. “They are cumbersome and very expensive, and computer processing and graphic display technologies were just not there. But processing power and graphic technologies are expanding exponentially—they increase every six months. Simulator training will impact the world of training as greatly as assembly lines affected the manufacturing industry in the early 1900s.”

Introducing Cat Simulators

Introducing Cat Simulators

Prior to licensing the business in late 2008, Caterpillar had simulators available for the hydraulic excavator, M-series motor grader, off-highway and mining trucks, and the large wheel loader. Simformotion has since added the small wheel loader and wheel tractor-scraper to the product line, and this fall, it will release its latest simulator, for the track-type tractor. The complete line of Cat Simulators includes the following machines:

- Hydraulic Excavator. Used for urban utility construction, sewer applications, trenching and truck loading.

- M-Series Motor Grader. Used for road maintenance and construction from finish grading to rock spreading.

- Small Wheel Loader. Used for truck loading from stockpile at construction sites and quarry operations.

- Large Wheel Loader. Used for aggregate truck loading at mining or construction sites.

- Off-Highway Truck. Used for hauling at construction and mining sites.

- Mining Truck. Used for hauling at mining sites—very large capacity.

- Wheel Tractor-Scraper. Used for moving large amounts of dirt at construction sites.

- Track-Type Tractor. Used for land clearing and rock ripping at construction and quarry sites.

Upon taking over the contract, Simformotion’s first simulator product, for the hydraulic excavator, shipped to N C Machinery, a Caterpillar dealer in the Pacific Northwest. The firm also received an early contract with the U.S. Army to develop, deliver and set up 31 small wheel loaders at the Army Engineering School at Fort Leonard Wood, Missouri.

The manufacturing chain is entirely local, something in which the company takes great pride. Parker Fabrication, also in Morton, bends the tubing for the frame, while up the road in Roanoke, Parsons Company forms the flat metal and paints them according to Caterpillar color specifications. Peoria-based Shamrock Plastics manufactures the casings for the controls, which are actual controls for real Cat machines, obtained directly from Big Yellow. Upon completion, the simulators are received at Simformotion’s warehouse in Morton, where they are assembled and shipped to waiting customers. Turnaround time from order placement to shipment is less than 30 days.

Why Simulators?

“Simulators are not replacing ‘in-the-iron’ training—being on the actual machine,” said Annette Bailey. “The simulators are part of the training program. Nothing is going to replace that operator actually operating a real machine.” So why train on a simulator in the first place?

Foremost among the many reasons is safety. An untrained (or undertrained) operator can cause a lot of damage to him or herself, to the jobsite or to the machine. The simulated environment is a safe place to gain familiarity with the controls and master operating techniques before moving up to the real thing. If the operator makes a mistake, he or she merely runs the exercise again. By pre-training operators, potential mishaps can be avoided altogether.

A second benefit is the impact on production. Actual machines are not taken away from production sites to be used in training, nor are they subject to misuse by untrained operators. Engine life is longer, and reduced maintenance means that they stay in use longer. Difficult maneuvers can be practiced repeatedly, and bad habits corrected. Operator contribution is the cornerstone of productivity on a job site—the more skilled the operator, the more efficient the process.

Cost savings and flexibility are other obvious benefits. Mishaps in the simulated environment cost the company nothing. There are no fuel or maintenance costs, and actual machinery remains available for billable work. A single instructor can train multiple operators on multiple machines at the same time, at any time of day or night, regardless of weather conditions, and training modules can be customized for specific operators. In addition, the insurance costs associated with training on heavy equipment can be lowered.

Finally, simulator training makes an excellent tool for HR and recruiting. When employees are in charge of multi-million-dollar machinery, the importance of finding the right people is elevated to a whole new level. Using simulators, potential employees can be evaluated on their knowledge and aptitude for learning. Training records management software allows performance benchmarks to be recorded and tracked in a consistent manner. Potential hires that lack competency can be screened out, while the strengths and weaknesses of current employees can be identified, and further training needs can be assessed.

Features & Exercises

Features & Exercises

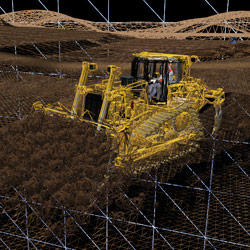

Each Cat simulator consists of a combination of PC-based software and simulated equipment hardware. The operator’s chair sits on the base of the steel H-frame assembly behind an adjustable steering column, with gas and brake pedals mounted to the floor plate. The left control pod serves as an arm rest and houses a keyboard, while the right control pod contains switches, joysticks, levers and other controls representative of the actual machines. A large monitor in front of the assembly displays the simulated worksite—exactly as it would be seen from the cab—while a second monitor behind the operator displays the rear view.

The simulators feature training exercises that allow the operator to gain familiarity with the machine’s controls and learn basic operation techniques. Such exercises include:

- Machine Walk-Around. Learn pre-operation inspection procedures to ensure proper operating and safety conditions.

- Controls Familiarization. Learn the controls and proper sequences for machine operations, including start-up and shut-down procedures.

- Steering & Maneuvering. Learn proper techniques to safely maneuver the machine around the jobsite.

- Blade Steering. Learn proper techniques to utilize the machine’s blade steering capabilities.

- Truck Loading. Learn to scoop dirt into the bucket and dump its contents into the truck.

- Trenching. Learn to use the bucket to excavate a small trench.

- Backfilling. Learn to use the loader to backfill a slot ditch and level to existing grade.

- Unloading. Learn to dump a load of material while maintaining a smooth and even pour.

Bundled with each simulator, the highly configurable SimU Campus software records and reports operator performance in each exercise. Instructors can set up classes, select training exercises and configure pass/fail thresholds for individual metrics. Interactive eLearning companion courses are also available. As befits the products of a global corporation, the software is available in English, Spanish, French and Chinese.

Upon client request, exercises can include random “incident events,” such as reduced visibility, low engine oil pressure, flat tires, brake or hydraulic failure, obstructions in the road or operator fatigue. Other options are available to expand the simulator’s functionality so that training can be customized according to the curriculum and students’ individual needs.

Taking a Test Drive

During my August visit to CSE Software, I was able to take the small wheel loader for a test drive. The experience was somewhat akin to playing an arcade game like Rush—minus the thrills of street racing, and with a much higher degree of real-world significance. This is serious gaming, after all.

Each exercise begins with the basics—fasten seatbelt, turn key, start engine—before moving on to the task at hand, from basic driving to backfilling and blade steering. In addition to the first-person view from inside the cab, you can also kick out to observe the machine from the outside. The environment is designed to be as realistic as possible, from the roar of the engine when it starts up—actual sounds recorded in a studio at Caterpillar—to the “deformable” terrain of the worksite, modeled after real-world construction and mining sites. Everything is physics-based: if you collide with an object, it will move as it would in real life. And yes, if you’re wondering, you can crash into that Porta-Potty.

But if you crash the machine, a critical failure will occur, and the simulation will come to a halt. Otherwise, upon completion, exercises end with the basic shutdown procedures—engage service brake, engage parking brake, turn engine off. Data is then sent to SimU Campus, which processes and analyzes the results. Hundreds of different metrics are measured, such as: number of times off course, total distance maneuvered, maximum/minimum/average speeds, average blade height, blade tilt angle, number of bucket collisions with the ground, and amount of material spilled between zones. Each metric receives a pass/fail grade.

It’s not at all hard to appreciate how beneficial the simulator experience would be to a machine operator in training. Anyone who’s learned to ride a bike, honed their swing in a batting cage or played a musical instrument can grasp the importance of muscle memory. The simulators’ realistic controls and first-person point of view ensure that when you hop into the cab of a real machine for the first time, you’ll feel right at home.

Meet the Development Team

Meet the Development Team

Prior to landing the simulator business, the CSE development team was already familiar with the territory, having written the SimU Campus software that comes bundled with the simulators. To prepare for the simulator work, they investigated nearly 20 different 3D gaming engines, attended a national gaming conference in Austin, Texas, and spent time developing simple 3D games, both for research and for fun.

They now serve as a dedicated team for CSE’s simulator business. And a team it is—the six developers share close quarters in the same room, and their work, by necessity, overlaps to some degree. The room also contains a working simulator, so the team can rebuild software on the fly and test changes to the code.

The design process begins with the modeling of an actual working machine, using manufacturing specifications, photographs and illustrations for reference. Tim Lindsey, 3D modeler, models the environment and terrain down to the trees, vehicles and other objects, and refines it to fit the unique criteria defined by the client. “The most challenging aspect of my job is creating models efficiently and knowing when to call it done,” says Lindsey. “You can spend lots of time tweaking and fine-tuning.” When he is finished, Jason Barker, 3D texture artist, creates all of the real-world textures, skins and surfaces, resulting in life-like color and depth to the scenes.

Programmers Jade Skaggs, Brandon Reynolds and Mike Lyons then program the model to operate as the machine would in a real-world environment—moving dirt, pushing around objects and the like. “I primarily do the physics development to make it operate like the real machines would,” says Skaggs. “We go out to [Caterpillar’s training facility in] Edwards and capture video, and we also get engineering specs and use that data to simulate the machine as closely as possible to real-life operation.”

“Handling the user interface, shadows, dirt interaction, translations, training exercises and communication with our SimU Campus software are a big portion of my duties,” adds Reynolds. “Pretty much anything outside of the vehicle physics, modeling and texturing.”

Audio is captured from the machines and embedded into the software to accentuate the virtual experience. Actual worksite scenarios are recreated as realistically as possible, and subject matter experts are consulted to create optimal benchmarks for the training exercises. Quality assurance tester Andy Grabenstetter then tests the simulator to ensure that it meets required specifications and functionality with no bugs or defects.

The most challenging task for the developers is to create accurate physics simulations with limited processing power. Each chunk of dirt in the simulated environment, for example, has physics behind it—and there are thousands that must be rendered. “That’s something real-world physics doesn’t have to worry about,” notes Skaggs.

“Because you have a ‘live’ simulator and the PC is constantly processing data, the limitations of the hardware are the biggest factors,” adds Barker. “For instance, Avatar—which is the pinnacle of computer graphics—took years to render the animations.” Cat Simulators, on the other hand, must render the simulated environment in real time.

Designing the Hardware

The simulators’ hardware is designed to work in tandem with the software. While software companies historically tend to steer clear of hardware and vice versa, Simformotion handles both in-house. In one sense, it’s a bit like the vertically-integrated Apple Inc., which has seen many advantages to handling both the hardware and software sides of its products.

“I think it’s a huge benefit to have it all in-house,” says Stacey Burris, project manager for 3D development. “We know what the client wants, and we’re able to parlay that into a product that is seamless because [both sides] can work together. They are cohesive from the beginning.”

TJ Cassidy, CSE’s on-staff engineer, designs the hardware for Cat Simulators, replicating each machine’s cab as closely as possible while keeping the design cost-effective. He uses Cat controls, steering columns, pedals and switches to create an accurate replica of the machine so operators can get the most realistic experience possible.

The simulators’ control pods, steering columns and pedals were designed to be easily swapped out so that customers can run multiple machines on a single frame. This helps organizations keep costs in line and addresses any space constraints they may have. Cassidy notes that “creating commonality among all simulators” is his greatest challenge. “The goal is to have a base simulator that can be quickly changed from one machine to another,” he said. “With the large variety of cab layouts and controls, it makes it difficult to incorporate them all.”

The trade-off between features and cost is another significant factor to be considered—the design must be cost-effective. For that reason, you won’t actually feel a tactile sensation when the machine blade hits the ground or the bucket scoops up dirt. It’s not that this is impossible, but such a feature would come at a prohibitively high cost. While it would certainly enhance the simulation, it’s not at all necessary for the task at hand: familiarizing the operator with the machine and its controls.

Simulation is the Future

Simulator sales are on target to double this year over last, and the company is actively seeking new markets. “The future of simulator technology is unlimited and will expand quickly into every market that requires operator training,” proclaims Ken Pflederer. To this end, CSE’s virtual environments can be developed for any organization and any type of training—not just for heavy equipment.

“Our experience right now is with the machines, but we have the technology and development smarts to render any type of environment,” says Annette Bailey. “Imagine a park, for example. You could simulate an environment to show where all of the trails, picnic areas, scenic views and wildlife are located. You could also show any dangers to be aware of, like cliffs, falling rocks, slippery areas or wildlife, in the 3D environment.”

“Another good example would be drivers education—putting the students behind a car simulator before getting into the actual car,” adds Burris. “The same type of safety concepts apply.” Simulators could be put to great use at educational facilities and correctional institutions, or in disaster preparedness training. While the company has not picked up any such work yet, it is currently in the proposal stage with several non-manufacturing companies.

“Since we took the entire serious gaming development in-house in 2009, we literally have a line at the door, packed with prospects who need a similar product,” says Pflederer. “So, you ask about the future of CSE? Incalculable.” iBi